It all starts with the forest. In Estonia, forests cover over half of the land area, totalling 2.3 million hectares. Pine wood, in particular, is highly valued for its strength and durability, making it an ideal material for producing high-quality mouldings.

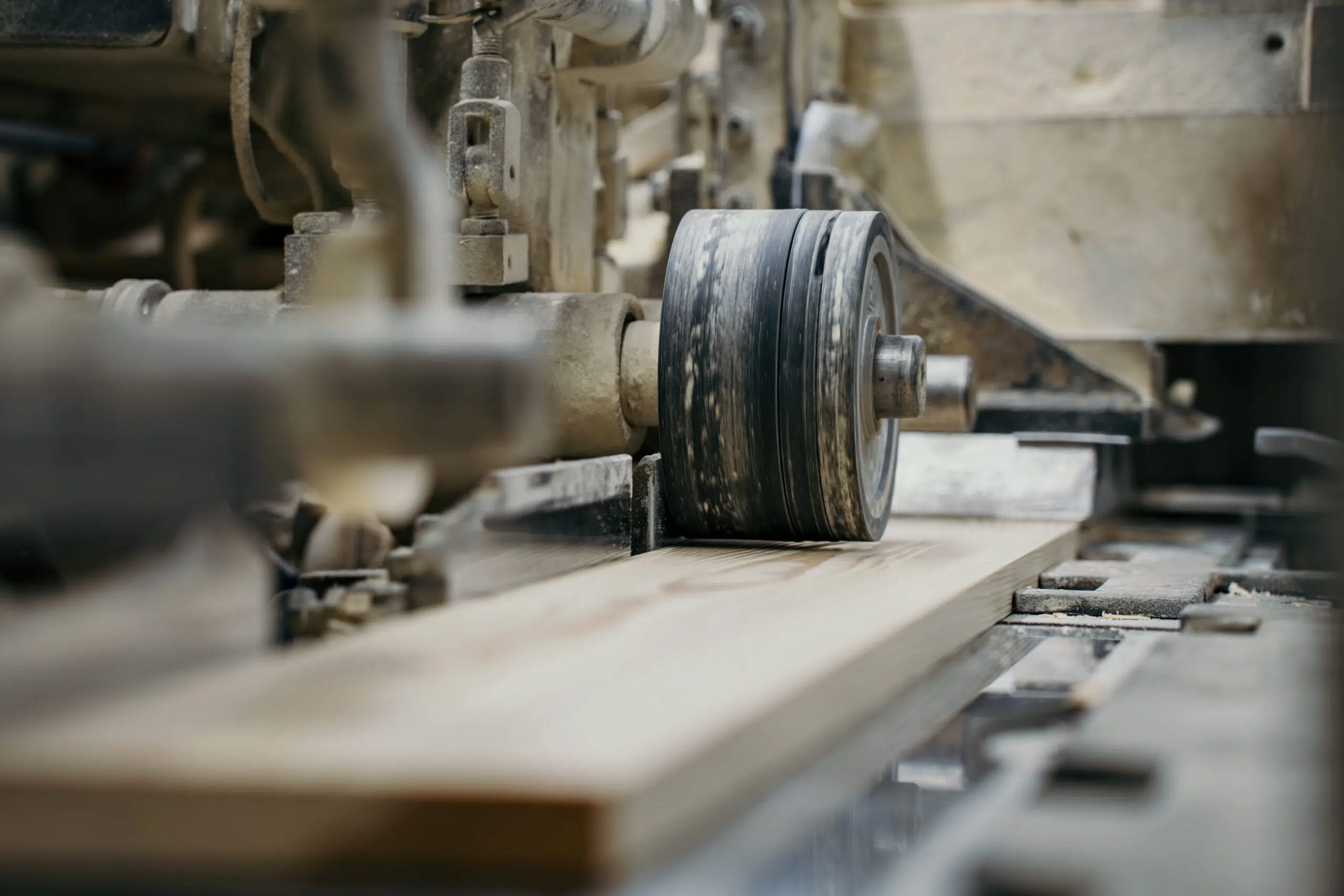

Mature pines are delivered to our group’s sawmills, where the round logs are sawn to precise dimensions. The right cutting plan ensures the best wood quality and optimal yield.

The sawn timber then goes into the kiln, where it reaches the required moisture level within 1–2 weeks. Drying is a precise science — even the slightest error can compromise the material.

The dried timber moves on to the component factory, where finger-jointing takes place. A scanner and automatic saw remove all defects from the wood — including knots, resin pockets, and cracks. The defect-free wood blocks are then rejoined in the finger-jointing machine, producing knot-free moulding stock in precisely the desired lengths, such as the 2.2 or 4.4 metres commonly required in Scandinavia.

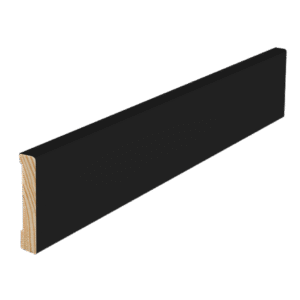

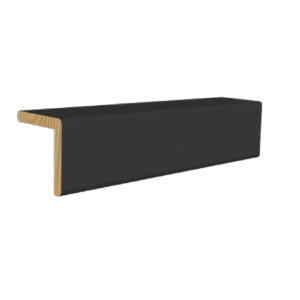

The raw material moves on to our moulding factory in Helme. Here, components are cut into smaller sizes if needed and then planed into precise moulding profiles using a four-sided planer. This is followed by automatic – and, if necessary, manual – puttying to eliminate even the smallest imperfections.

The mouldings then move to the painting line, where they are sanded and coated first with primer and then with topcoat. The finished mouldings undergo thorough quality control, are labelled with barcodes, and are carefully packed for transport.

From pine log to finished moulding, the entire process takes at least two to three months. Behind this is the smart collaboration between the different companies within the Combiwood group, resulting in high-quality mouldings that are delivered to Estonia, Scandinavia, and across Europe — enhancing thousands of interiors.

Check out our selection of mouldings HERE